EYE+

EYE+ consists of a compact controller, a high-resolution camera and a calibration plate. This plug and play system running on the easy to use EYE+ Studio web based interface that requires no in-depth knowledge of machine vision to run your flexible pick and place application. EYE+ Studio also makes it easy to configure the vision, perform hand-eye calibration, change recipes and program new parts.

EYE+ advantages

Easy to use: No previous experience of machine vision required to setup and use EYE+ resulting in faster installation and lower setup costs.

Intuitive recipe creation and configuration: User friendly interface, with step-by-step instructions and explanations, makes the software easy to follow. Have a complete new system with calibrated robot and vision setup within minutes. New recipes can be learnt in a fraction of the time compared to conventional models.

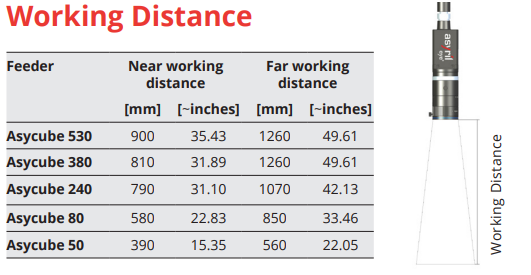

Plug and play: Designed to easily integrate with any size of Asycube and any industrial robot for hassle free set-up. Simple direct connection and pre defined vision parameters with help tips and graphics mean installation, mounting and setup can be quickly performed without any prior experience.

All included: Simply accessible via a web browser, no software download or additional licensing required. No 3rd party software or hardware required for a complete system.

Attractive: Highly competitive system costs compared to traditional solutions.

Compatible with any PLC & industrial robot brand: Command prompts are sent through TCP/IP so EYE+ is compatible with any robot brand giving pick point location for any part.

How it works

Using the configuration wizard, EYE+ Studio set up in 3 easy steps:

Vision configuration

Create a new recipe

Hand-eye calibration

During production, EYE+ controls all the different components of the application (Asycube, hopper, vision and robot).

1. Switch on the hopper to feed the Asycube

2. Manage the right vibrations of Asycube

3. Detect correctly oriented parts

4. Pick parts from platform by robot

SCHEDULE A DEMO

Don’t let the future pass you by. To schedule a complementary on-site demo please fill out the form below.